Bongard operation manual BONGARD means Oven History: 1922 - 2006 1922 Oscar BONGARD founded the BONGARD company Operation in manual mode Operation in automatic mode with storage Cervap Os max fs 70 surpass manual. The Opticom can be used in manual mode by a pastry chef or baker or simply in “recipe” mode by a less experienced user. Operating principle. In recipe mode: just one push on the Start/Stop button and baking mode will be automatically started. Features of Opticom for rack ovens: Setting and display of pre-heating temperature.

Working with flour is like talking to it while trying to guess its whims.

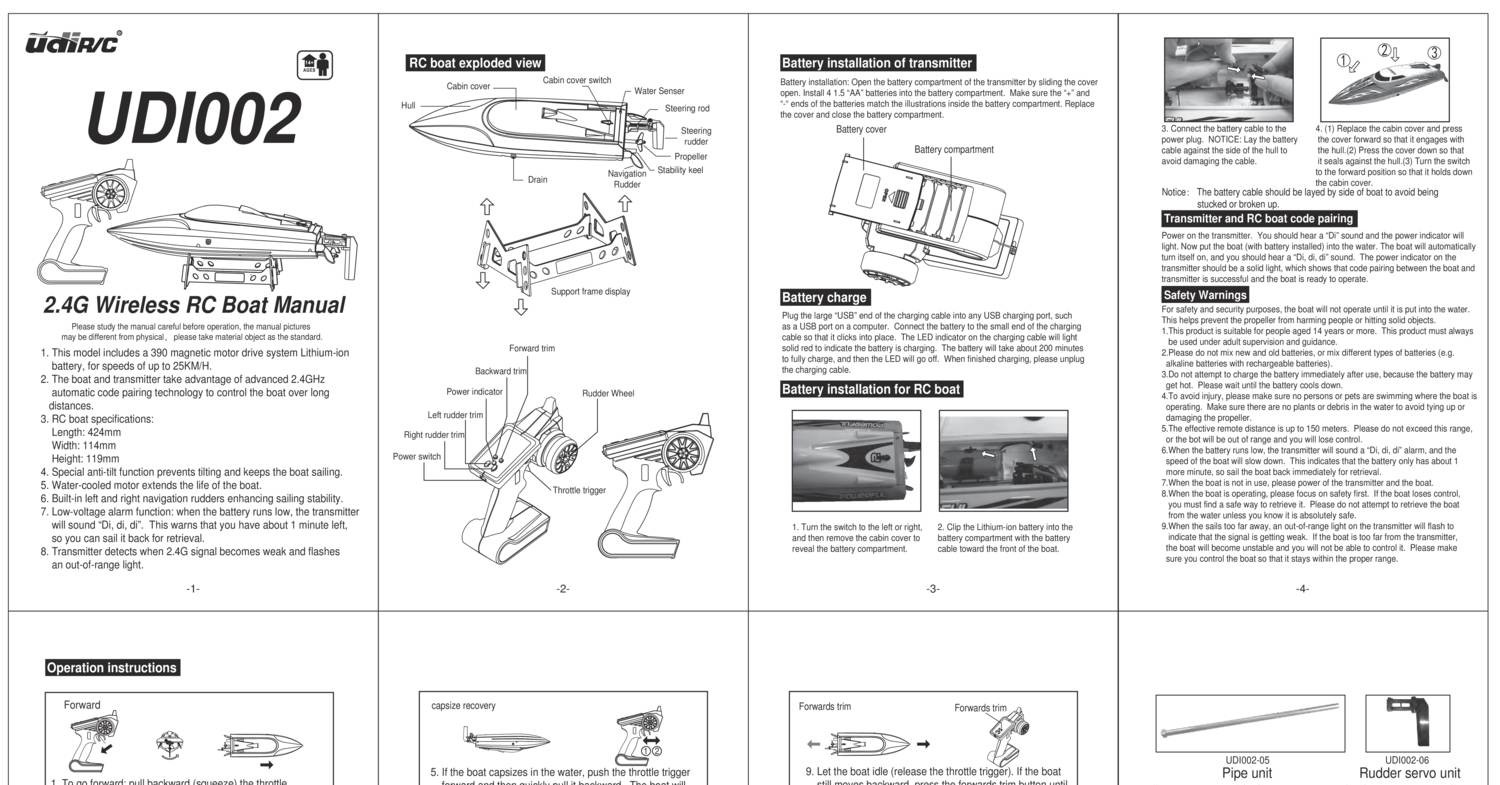

- . Operation in manual mode. Operation in automatic mode with storage of 30 recipes. Optimised preheating which takes account of the residual oven temperature. Automatic starting according to the required baking time. Automatic starting for each deck. One possible alternative per deck. Stopping of the burner. Timed and pulsating steam injection. Adjustable speed of exhaust.

- The LCD displays message 'RETARDER TIMINGoooo' to indicate the retard operation is running with timer (See Fig. To stop the retard timer, press timer START/STOP button. To stop the retard operation, press 'CHANGE MODE' arrow button or ON/OFF button. LED is on indicating the unit is running.

Any baker or confectioner knows the importance of chilling, cooling, deep-freezing, and necessary fermentation of dough. Our fermentation rooms, deep freezers, conservation units and drying cabinets are active participants in your manufacturing process for you to get the best finished product!

Retarder-Proofer

The Bongard “BFC” roll-in retarder-proofers are used to slow down and control proofing of dough pieces over a certain period of time defined by the user.

The principle of operation: The dough pieces are stored in the retarder-proofer between 2°C and 4°C to retard proofing.

Once the control panel has been programmed, the ‘BFC’ automatically manages the changes in temperature based on the settings previously entered by the user.

Characteristics

• Structure made of 60 mm thick isothermal panels

• Product is custom made• Inside lighting

• Can also be set to a warm temperature cycle, up to a maximum of 30°C

• Different sizes of chambers available, depending on models

• Possibility to place retarder proofer chambers side by side

• Delivered without racks

Capacity

• Chambers of 800, 1000 or 1200 mm

• Racks of 400×600 mm, 800×600 mm, 700×900 mm, 750×900 mm and 1215×800 mm can be housed, depending on models

Proofing Cabinets

The Bongard “BFA” and “BFP” proofing cabinets work in the same way than the “BFC” does. They are considered as cabinets and not chambers, meaning that they contain tray slides and not racks. They have a capacity of 20 levels, ranging from 400×600 to 1115×800 mm.

Characteristics

• Large range of models

• Adjustable humidity level (30-90%)

• 3 wheels and 2 adjustable feet on the front make it easy to move

• Can be used as a pastry or a bakery unit, with its U-rails cabinets

Capacity

• 20 levels for tray slides of 400×600 to 1115×800 mm

Proofing Chamber

The “BFE” proofer is used to reach a set temperature (30°C-40°C) very rapidly. It is a chamber that is used for fast proofing of baking and pastry products.

Characteristics

• Made of 60 mm thick isothermal panels

• Custom made product

• Inside lighting

• Can place the chambers side by side

• Delivered without racks

Capacity

• Chambers can contain racks of 400×800, 600×800, 700×900 and 800×1000 mm

• Interior dimension of chambers: 800 mm, 1000 mm or 1200 mm

The “BSP”

The blast freezing ‘BSP’ from ‘Bongard’ is designed to blast chill and blast freeze the product before conservation. The ‘BSP’, with its electromechanical actuator, autonomously controls the temperature and time needed to freeze products. Once this temperature has been reached, it regulates it for 24 hours and automatically switches to storage mode at the end of cycle.

Characteristics

• Fast freezing mode

• Electromechanical control

• Easy to move

• Interior in stainless steel makes for easy cleaning

• Switchable door side

Capacity

• 3 available models of 5, 9 or 15 shelves of 400×600 mm

Bongard Operation Manuals

The “BSC”

The ‘Bongard’ roll-in ‘BSC’ blast freezer is designed to chill and rapidly freeze products before conservation. Its electromechanical control autonomously controls the temperature and time needed to freeze products. The BSC is capable of controlling cold production to reach -18°C as quickly as possible. Depending on the model, 30 kg to 130 kg of raw baguettes can be blast-freezed per hour.

Characteristics

• Buzzer sound indicates the end of the pre-cooling and whole cycle process

• Sheet panels and screws made of stainless steel

• Alternated display of temperature at core and actual time

• Easy cleaning

• Special ventilator for deep freezing

Capacity

• 4 models available

• They can accommodate racks of 400 x 600mm, 600 x 800 mm and 800 x 1000 mm

BLAST CHILLERS

“Speed”, the line of blast chillers from the brand Afinox provides a very fast chilling and freezing. They are modern and ergonomic devices that allow for the recording and downloading of HACCP data through a USB port. Several models of different specifications are available.

Characteristics

• Interior and exterior structure made of stainless steel

• Automatic or manual blast chilling

• Automatic or manual shock freezing

• Thawing, defrosting and optional sterilisation functionalities

The “BSCP”

The Bongard “BSCP” is designed to chill and rapidly freeze products before conservation. With this single equipment, bakers and pastry chefs can chill, freeze and store their products conveniently. Once the desired temperature has been reached, the “BSCP” controls cold production for 24 hours, then automatically switches to conservation mode when the cycle ends. Then it’s just a matter of moving the trays from the blast freezer towards the conservation compartment.

Characteristics

• Dual functionality: blast freezing and conservation mode

• Space saving• Time saving: less time spent handling products

• Buzzer sound indicates the end of cycle

• Manual defrosting for the blast freezer, automatic and/or manual for the conservation unit

Capacity

• Can contain 9 shelves of 400×600 mm

Bongard Operation Manual Transmission

The “BCP”

The “BCP” conservation unit is designed for the conservation of products after blast freezing. After the freezing process, the products are stored in the device at a temperature of -18°C/-22°C.

Characteristics

• Structure made of 80 mm thick isothermal panels, 90 mm thick for the floor

• Comes with an electromechanical control interface (optional electronic control)

Capacity

• Storage capacity of 26 to 146 shelves of 400×600 mm’

The “BTP”

The “BTP” refrigerated workbench from Bongard is designed to store pastry products. Fresh products are kept in a conservation unit that is completely isotherm, with temperatures ranging from 0°C to 10°C on 400×600 mm trays. Ventilated cold maintains an even temperature throughout the cell.

Characteristics

• Regulation done by an electronic thermostat

• Interior and external panels made from stainless steel

• Easy to clean

• Adjustable legs

Capacity

• Workbenches available with 2, 3 or 4 doorsStorage capacity of 8 levels per section, i.e., 16 to 32 shelves of 400×600 mm

Positive cold

From the Swiss/German brand Liebherr, we bring you the BKPv 6520. A refrigerator that has been specially designed for the baker’s use, it’s a robust, compact, 600 litre piece of equipment.

Characteristics

• Interior made of chromium-nickel steel

• Digital temperature control system

• Forced air cooling system from de -5° to +15°C

• Body made of stainless or bright steel

• Automatic defrosting using hot gas

• Built according to ISO 9001 :2000 and ISO 14001 standards

• Storage capacity of 20 400×600 mm shelves

• Stainless steel tank with rounded angles and discharge of cleaning water

• High-density insulation of 83mm, with no CFC

• Operational at ambient temperatures, from +10° to +43°C

• Condenser protected by a dismountable dust filter

• Frontal technical access, via a raisable panel

Negative cold

The BGPv 6520 from the Swiss/German brand Liebherr is a 600 litre compact refrigerator that provides negative cold.

Characteristics

• Body made of stainless steel (galvanised rear) or bright steel

• Forced air cooling system from de -35° to -10°C

• Steel interior

• Storage capacity of 400×600 mm, with 20 shelves

• Digital temperature control

• Automatic defrosting using hot gas

• Built according to ISO 9001 :2000 and ISO 14001 standards

• Stainless steel tank with rounded angles and discharge of cleaning water

• High-density insulation of 83mm, with no CFC

• Operational at ambient temperatures, from +10° to +43°C

• Condenser protected by a dismountable dust filter

• Frontal technical access, via a raisable panel

You wish to be kept updated about our new products, services and industry trends? Sign up to our newsletter here.

DOS & DON’TS: [√] Do Follow Manufacturers’ Instructions for Equipment

- 02.08.2017

- Posted inCompliance & Risk Management, Equipment Safety, Materials Handling, Workplace Hazards

- 0 Comments

When it comes to the machinery and equipment in your workplace, it’s important that you comply with the requirements for such devices in your jurisdiction’s OHS laws. You may also have to comply with any applicable voluntary standards, such as those from the CSA, that have been adopted by the OHS laws. However, there’s another source of safety information you should also comply with but may overlook—the instructions from the manufacturer of the equipment or machinery. These instructions are specific to the operation of that particular make and model of equipment and so provide important information on its safe use. And the OHS laws may specifically require you to comply with manufacturers’ instructions. For example, Sec. 12(d) of Alberta’s OHS Code 2009 says an employer must ensure that equipment and supplies are erected, installed, assembled, started, operated, handled, stored, serviced, tested, adjusted, calibrated, maintained, repaired and dismantled in accordance with the manufacturer’s specifications or the specifications certified by a professional engineer.

Look what happened to small family farm in Ontario that ignored the manufacturer’s requirements for a sweep auger located in a dryer bin. One end of the sweep auger was fixed in the centre and the other end moved in an arc across the floor, moving the soy beans to the center. According to the auger’s operating manual, no one should enter the bin unless the power to the auger was disconnected and locked out. But a worker swept beans into the bin while the auger was rotating. His clothing got tangled in the auger and he was thrown forward into its path. One of his legs got caught under the auger and suffered a laceration and soft tissue damage. The farm pleaded guilty to failing to ensure that the manufacturer’s instructions for safe operation of the auger were complied with and was fined $18,000 [Willow Hawk Farms Inc., ON Govt. News Release, July 30, 2014].